South Africa's widest range of Nitrile and PVC solid woven belting.

The latest generation of Fenner Conveyors' Cut & Gouge Resistant cover compound is the perfect solution for improved reliability, throughput and conveyor life.

We manufacture and supply high-quality and comprehensive conveyor belt solutions to the South Africa market.

A Better Way Forward

MATERIALS MOVEMENT PORTFOLIO

Conveyor experts across a diverse range of bulk handling applications

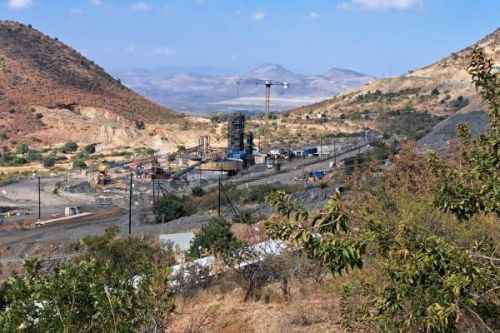

Mining

Ports

Processing

Agriculture

Our Vision

As part of the Michelin Group, we are committed to an "All Sustainable" approach; we strive for the best balance between people, the planet, and economic and financial performance.

For People, this means development, commitment, safety, the inclusion of diversity in all its forms, and value creation for our customers.

For the Planet, this means achieving carbon neutrality and product circularity.

For Profit, this means growth, financial value, brand power, and innovation of our conveyor products, services and solutions.

This translates into our actions around People, Profit, and Planet.

New Textile Reinforced Manufacturing Capability

Our Customers

Seriti - Kriel Overland Project

13,137 metres installed in 2012 - DynaFlight belt. Belt still running. Fenner Conveyors supplied, spliced and installed this belt.

Sasol - Tweedraai Project

8200 meters installed in 2016 – DynaFlight belt. FCB do visual inspections on this belt monthly.

Sasol - Shondoni Incline Belt Project

1800 meters installed in 2016 – DynaFlight belt. Belt still operational with spare belting on a back-up system ready for installation.

Sishen - Kolomela Replacement Project

1300 metres installed in 2013 – Currently still in use and this belting is being utilized throughout the mine. The system is a non-electronic system to assist with belt ripping.

South 32 - Hillside Project

Installed 800 meters in 2015, 2020, 2021, 2022 - Dynaflight Belt. Hillside are currently buying HR and Type F Textile belting and Type F Steelcord belting from Fenner Conveyors SA.